Feature:

★Allowing the heavy machine to be transported to the floor before lifting the floor to prevent the floats from bursting during transport.

★There is no wood plywood between the floor, so the risk of fire can be reduced to a minimum

★Can completely avoid the wood splint and concrete between the short circuit problem and shock.

★The main materials of the jack-up floating flooring include polyethylene waterproof adhesive tape, low dynamic stiffness rubber jack-up shock absorber, steel, concrete and insulation board. Low dynamic stiffness rubber self-propelled shock absorbers have different sizes, each with different load and deformation, shock absorber with mold casting bell-type shell, lifting insulation and stop screws are included in the bell-type shell, So that the floor to enhance more easily. Insulation board is installed around the wall. If necessary, install the drain on the floating floor.

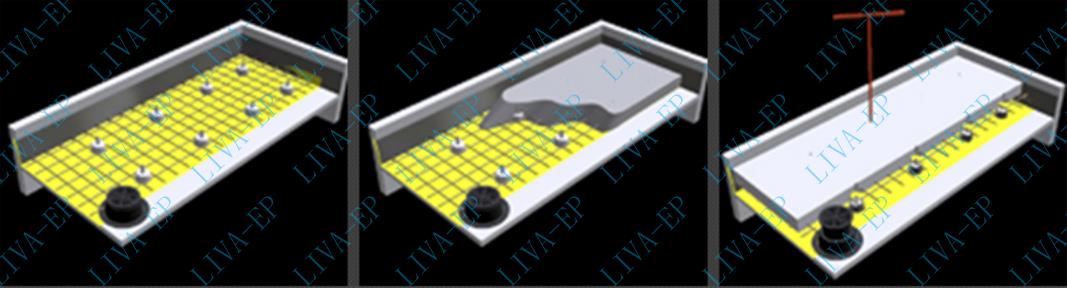

Installation method:

1. First covered with 0.15 mm thick polyethylene tape on the floor, and then the low dynamic stiffness of the rubber jack-up shock absorber on the average platform, plus steel, and finally pouring concrete and waiting Its curing. To float the floats, first pull out the shields of the shock absorbers, and then rotate the screws on each shock absorber in order to lift the floating floor.

2. After the lifting floats rise, they can form an air layer at a specific height from the platform. The air layer also becomes an insulating layer, which can effectively sound, shock and shock. Can also lay the sound insulation cotton, increase the sound insulation effect.